Structural Group:

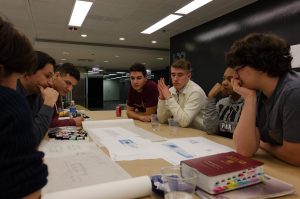

The structural group studied the preliminary floor plans from the architecture group and discussed whether the column locations were sufficient to support the building. We discussed different structural framing schemes that might work for what the architecture group had envisioned. In the end, we concluded that more columns would have to be added to support the structure and met with the architecture group to discuss our concerns and brainstorm solutions. A few structural schemes were discussed and next week we will find out which scheme the architects prefer.

Construction Group:

The construction group reviewed site logistics plans from the week before and worked towards finalizing the haul roads and site boundaries. We then explored scheduling and discussed the creation of Gantt charts using P6 software and Microsoft Excel. The mentees were introduced to critical path analysis to find the schedule duration and activities that are on the longest path of a construction project. Now that we have an understanding of the way a schedule is developed and analyzed, we will have to determine the activities and durations required for our project .

Architectural Group:

This week the architecture group explored the form of the building through section, elevation, and plan. The students established programmatic details and rough materiality for the exterior of the building. The MEP and Structural groups had many space and use related questions which spurred discussion and collaboration in the design process. Next week we plan to finalize our concepts and prepare for an upcoming client meeting.

MEP Group:

The MEP group started off with plumbing, figuring out the pipe sizing requirements. We will continue with these calculations next week. Next, we moved on to HVAC and mechanical room sizing. We covered some calculations used to determine energy use for space conditioning and ventilation. We used rules of thumb to estimate the equipment and room sizes. We shared this information with the Architectural group and explained the minimum area required to house the mechanical equipment, and approximately how many toilet fixtures would be required for this occupancy. Together we reviewed options of how to incorporate the mechanical requirements into the design. Luckily we all agreed that exposed ductwork will be a suitable design solution for this space!