Will there be enough architects, construction managers and engineers to fill the industry’s needs ten years from now?

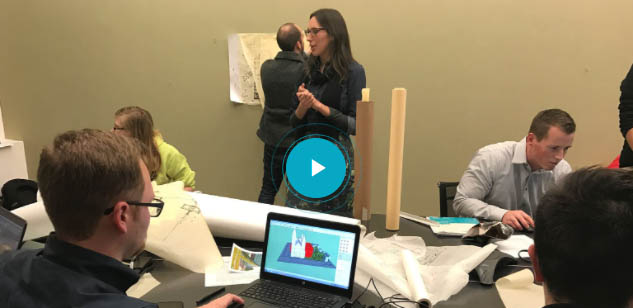

The ACE Mentor Program is working hard to make sure there will be. The national program was founded in 1995 as an innovative way of attracting students, particularly students of color, women and low-income populations into careers in the architecture, construction and engineering industry. ACE’s mission is to inform and excite high school students about career opportunities in architecture, construction and engineering; encourage students to pursue secondary and post-secondary education that will prepare them for careers in the integrated construction industry; and support the development of basic and technical skills through mentoring relationships.

The ACE Mentor Affiliate of Chicago was established in 2000 and has a 19-year partnership with the Chicago Public Schools (CPS). Since our founding we have touched the lives of more than 3,500 high school sophomores, juniors and seniors from 36 Chicago public schools. ACE Chicago places a special focus on recruiting students of color and female students; groups that are significantly under-represented in the construction and design industry, and in professional occupations overall. 93% of participants are minority and 30% are female.

ACE Chicago by the Numbers

FOLLOW US ON INSTAGRAM ACEMENTORCHICAGO